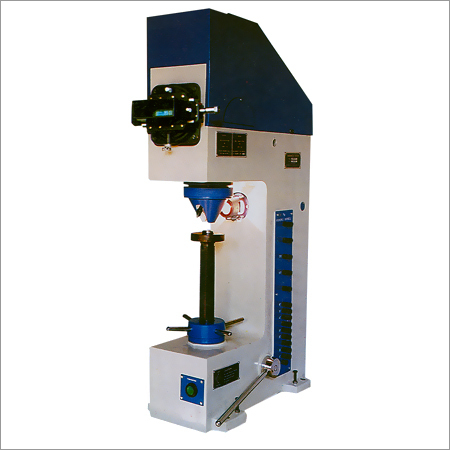

Analogue Cum Computerised Universal Testing Machine

Product Details:

Product Description

Analogue Cum Computerised Universal Testing Machine

Computerised Control Panel

Load measuring system

The oil pressure in the main cylinder is also transferred to an electronic pressure transducer which gives a proportionate signal to the Data Acquisition Unit. Both. the motor for hydraulic operation and cross head motion, are controlled by push buttons and they have interlocks to prevent simultaneous working of the motors. The electrical panel is fixed on the control panel is fixed on the control panel. Displacement measurement is carried out by means of a Rotary Encoder. Encoder signal is fed to the Data Acquisition Panel to get displacement in mm.

Features of Data Acquisition Unit

- A Microcontroller based data acquisition system for data acquisition and indication.

- Two 16 characters x 2 line LCD displays for display load and crosshead travel value.

- Auto detection of over-load, over travel and specimen break. On detection of any of the above conditions, the machine is automatically switched off.

- Load is indicated with resolution of 0.01% of machine capacity for the entire measurement range ( in other words with a resolution of 0.04kN for TUE-C-400 Model )

- Tare load and reset elongation facilities available.

- Elongation is indicated with a resolution 0.1 mm.

- Storage space to store data of 1 off-line test.

- The Win UTM software can run a variety of mechanical tests, recall data from previous test and prepare test report.

- Menu driven software for easy of use.

- Test Reports and Graphs can be sent directly to the printer via parallel port or USB port.

- Storage and retrieval of test parameters.

- Display of load elongation (stress and strain are optional) at any instant through out the test.

- On line display of load Vs elongation or Stress Vs Strain characteristics during conduction of test. The plot is auto scaled and displayed.

- Selectable units (kN, kgf, lbf, mm, inch)

- Variable sample break detection.

- Load is indicated with a resolution of 0.01% of machine capacity for the entire measurement range of 2% to 100% of machine capacity.

- Elongation is indicated with a resolution of 0.1 mm.

- Provision of auto - Zeroing of Elongation at set pre-load.

- Tare load and Reset elongation facilities available.

- Auto - Detection of over load, over travel and specimen break. On detection of any of these conditions, the machine is automatically switched off.

- High precision sensors and encoders used for load and elongation measurement.

- Large storage capacity for storing data (upto 50,000 set) on the computer.

- Provision for calculation of parameters such as load and elongation at yield, peak load at break. Yield stress, ultimate stress etc. The Parameters to be calculated are user selectable.

- Test conditions, test data and test results are stored in a specific file based on a unique file structure.

- Built in facility for printing the test results and test graph from PC. A printer copy of consolidated test results conducted on a particular date can also be obtained. Graphs of Load Vs Crosshead travel, Load Vs Time, Crosshead travel Vs Time, Load Vs Extension, Stress Vs Stress etc. are available.

- Specific software for tensile, compression, Shear, Bend, TOR-Steel and other tests.

- If an Electronic Extensometer is used, then proof stress values (From 0.1% to 1.0%) can be determined.

- If an Electronic Extensometer is used, software prompts the user to remove Extensometer as soon as proof load id crossed. After removal of Extensometer, measurement of crosshead travel by the encoder commences and proceeds till completion of test. A combined auto scaled graph using Extensometer and encoder is available.

Other Products in 'Testing & Measuring Equipment' category

GST : 24AAECK9581F1ZC

|

|

|

|

KRUTAM ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |