Computer Controlled Universal Testing Machine (Servo Drive Ball Screw Driven)

Product Details:

Product Description

Computer Universal Testing Machine

A wide variety of tests can be conducted on this machine viz. Tensile, compressive, transverse, Peel test for adhesive tapes. The materials like rubber, plastics, ferrous metals, non ferrous metals, etc. can be tested as per different standards. The test specimens can have a number of forms like round, flat, threads, wires, dumbells, fabric, belts, straps, ropes, etc. or sometimes components directly also can be tested. In order to cater to this variety of forms, shapes and materials, a range of grips can be offered.

Description

The computer controlled universal testing machines are rugged, versatile, user friendly, accurate and can test a variety of materials. A wide choice of grips are available to suit the application. The windows based software is comprehensive and covers most of the applications. The automatic calculation of parameters from the observed test values, real time graphs, storage and retrieval of data are immensely useful. The state of art electronics, high quality material used, and the user friendly software makes the machine reliable and user friendly.

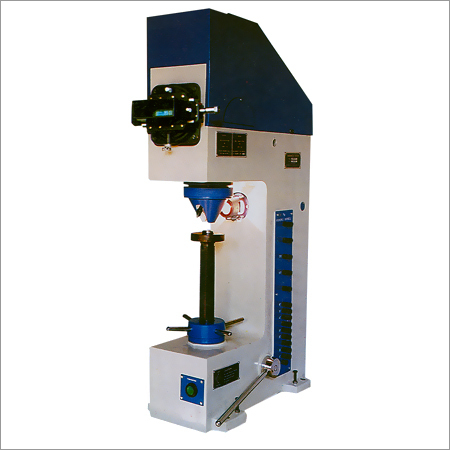

The machine comprises of a rigid assembly of lower table and top plate connected by guide rods. The two ball screws (One on left and the other on right) also are mixed in this assembly. The crosshead, in the center, houses the nuts of the ball screws. The entire assembly is fixed on the base, which accommodates driving arrangement base. A set of bellows protects the ball screws from ingress of dust.

The interface and computer are placed on a computer table by the side of the machine.

Standard Accessories

Basic machine along with one load cell and a pair of compression plates.

Windows based on users friendly software.

Salient Features

- Method of loading by re-circulating ball screws.

- AC servo motor for precise crosshead control with infinitely variable drive.

- Load measurement by load cell

- Over travel safety by fixed and settable limit switches at both ends.

- Overload protection for load cell by electronic control

- Single from windows based user friendly software

- Test data and reports are stored in access database

- User programmable strain rates in many steps

- User can select results from available result list for report

- User defined reports

- User can select test from templates and can start similar test

- Variable sample break detection.

- Tare load and reset elongation facilities available

- Load and Elongation is continuously displayed on screen

- Statistical output for a batch in report

- Simultaneous display of two graphs is possible in real time testing

- On line display of load and displacement (Stress, Extension, strain) etc. while test is conducted.

- Real time graph of load and Elongation, load and time, stress and strain is displayed and is auto scaled

- User selectable units for load and displacement (N, kg, kN, lbf, mm, inch, etc)

- Report can be printed on any printer with two graphs

- Large storage space for storing test data and results

- Provision of calculation of Load and Elongation at yield, peak load and load at break, Yield stress, Ultimate stress, etc.

- Specific software for tensile, compression, shear test and other tests.

- If Electronic Extensometer is used then proof stress values from 0.1% to 1% can be determined.

- software will give alert to user to remove extensometer when load crosses the proof load value

- In order to cover wide load range, more load cells can be supplied (optional), In that case has to select the load cell for test

- Standard load resolution is with 10,000 counts. Finer resolution with 20,000 or 50,000 counts can be offered (optional)

- Other slower crosshead speed on specific request (optional)

Technical Specifications

| Specification | Model | ||||||

| M1 | M2 | M5 | M30 | M50 | M75 | M100 | |

| Max. Capacity | 1 | 2 | 5 | 30 | 50 | 75 | 100 |

| Max. Crossehad | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Max. working | 400 | 400 | 400 | 400 | 400 | 600 | 600 |

| Fixed and working | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Overall dimension | 17/80x630 | 1780x630x | 1780x630x | 1700x630x | 1920x675x | 2640x1180x | 2640x1180x |

| Weight (kg) | 150 | 150 | 150 | 200 | 250 | 450 | 500 |

| Power Supply | 3 Phase, 415 V, 50Hz, AC | ||||||

| Overload protection | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| (Software operated and electronically operated in the event of load cell overload) | |||||||

| Drive System | |||||||

| Method of loading | By recirculating ball screws | ||||||

| Crosshead | AC servo with feed back | ||||||

| Crossehad speed | 0.5 to 500 mm per min. | ||||||

| Crosshead control | Computer controlled | ||||||

| Accuracy of | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

Measurement | |||||||

| Load | By Precision Loads cell's | ||||||

| Load Resolution | 10,000 counts standard (20,000 or 50,000 counts optional) | ||||||

| Load Accuracy | +-1% as per IS: 1828 – 1991 & BS:1610-1964 | ||||||

| Resolution of cross head displacement in mm | 0.01mm | ||||||

Other Products in 'Testing & Measuring Equipment' category

GST : 24AAECK9581F1ZC

|

|

|

|

KRUTAM ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |